According to Smithsonian Magazine, cannabis vaping can be traced back to 440 B.C., when the Scythians used red-hot stones to heat hemp seeds so they could inhale the smoke. Not nearly as long ago, in 1927, Joseph Robinson filed a patent for a medical device he called a “mechanical butane ignition vaporiser.” The Scythians and Robinson were high-tech innovators for their day.

The vaping landscape has undergone significant changes since then. According to market data firm Headset, vaporizers represented 23 percent of all sales on April 20, 2025 — better known in the industry as cannabis’s high holy day, 4/20. The reasons for the devices’ popularity are legion. They’re convenient. They’re discreet. Like combustible flower, vaping produces immediate effects, but unlike joints, vapes aren’t rendered irritating during a wind gust. Vapes also mostly dispense with the telltale “weed smell.”

Vaping’s momentum seems poised to grow. MarketResearch.com reported the market for cannabis vaporizers was worth $6.3 billion in the United States during 2024. That figure is expected to swell to almost $15 billion by 2030. Analysts attribute much of the predicted surge to technological advances, including increased battery life, customizable temperature settings, and Bluetooth connectivity.

Equipment manufacturers already are hard at work on the innovations that will define the next phase in vaping’s evolution. Here are some brands out in front of the trends.

Greentank Technologies

Founded in 2016 by brothers Corey and Dustin Koffler, Greentank Technologies is the only cannabis vape company with a Canadian federal research license allowing “oil-to-coil” testing on-site. “What distinguishes us in the industry is our ability to calibrate our products using actual cannabis extracts,” Chief Executive Officer Corey Koffler said.

One of the fruits of Green Tank’s sophisticated end-to-end testing and research is the Quantum Chip™, a revolutionary heating technology that eschews traditional ceramic cores. Instead, the product uses thousands of microscopic holes to channel oil toward a heating layer, which instantly vaporizes the liquid. “Quantum Chip technology harnesses microfluidics and capillary action,” Koffler said. “Think of an ultra-modern pump that smoothly draws cannabis oil through the chip to a heating layer where it is converted into vapor.”

Because the oil is heated only once rather than repeatedly cycling through a ceramic core, every puff tastes as fresh as the first, he added. More importantly, because the oil never touches ceramic or metal — both of which can degrade over time and leach particles into the vaping liquid—the potential for contamination is virtually eliminated.

The technology was developed in-house by Greentank’s team of more than 100 engineers, designers, scientists, and product specialists.

Quantum Vape by Greentank delivers smaller aerosolized particles and cooler vapor.

“We stepped back to rethink the very core of vape technology,” Koffler said. “Rather than iterating on outdated ceramic systems, we reengineered the ‘engine’ itself. Inspired by advancements in semiconductors and nanofabrication, it delivers cleaner vapor, richer flavor, and more consistent performance.”

The Quantum Chip forms the foundation for Greentank’s Quantum Vape™, which Koffler said produces smaller aerosolized particles that are more easily and efficiently absorbed by the body. Also of note: The Quantum Vape produces vapor that is up to 52 percent cooler than traditional vapes.

Quantum products are just the beginning of Greentank’s plans to make vaping safer, cleaner, and more fun for consumers. “Looking ahead, we’re also seeing strong momentum toward larger-capacity devices and smart features like LED indicators for oil levels, temperature control, and charging status,” Koffler said.

Artrix® Innovation

Instead of abandoning traditional architecture entirely, Artrix Innovation turned its attention to developing a next-generation system it calls high-conductivity ceramic heating cores. The technology overcomes many of the shortcomings associated with using traditional technology to vaporize evolving extracts.

“Live rosin is rapidly emerging as a premium choice in the high-end cannabis market,” according to Sylph Wu, Artrix’s digital marketing director. “Its solventless extraction process and rich terpene profile offer unmatched purity and flavor — qualities that discerning consumers increasingly seek. Yet, most vaporizers on the market are still optimized for distillates, not for the nuanced chemistry of live rosin.”

The mismatch results in uneven vaporization and significant loss of flavor, Wu said. “As consumer demand shifts from ‘high potency’ to ‘high fidelity,’ the hardware industry must evolve,” she said. “Live rosin users aren’t just chasing effects. They’re chasing experience: flavor, smoothness, authenticity. Premium extracts deserve premium hardware.”

Lilcube, a disposable all-in-one (AIO) designed for use with both traditional distillates and thicker extracts, is the company’s latest release to address the consumer-preferences shift. Every element of the device — from oil pathways to heating curves and material selection — has been reimagined with one goal: to unlock the full sensory potential of solventless oils. “Instead of compromising for broad compatibility, Lilcube delivers a tailored experience that enhances flavor consistency, vapor smoothness, and overall enjoyment for live rosin consumers,” Wu said.

Key features include:

- High-conductivity ceramic heating element provides fast and even thermal distribution.

- Crucible-style chamber with an embedded coil enhances oil absorption and minimizes the risk of dry hits.

- Center-tube-free architecture reduces contact with metal in the heating zone, preventing unwanted chemical reactions and preserving terpene integrity.

“Traditional ceramics often suffer from low thermal conductivity, which can create hotspots that degrade terpenes and alter flavor,” Wu explained. “Lilcube redefines ceramic performance through high-conductivity materials, delivering instantaneous heat response to preserve delicate terpene compounds; uniform thermal diffusion for consistent, clean vapor; and cotton-free oil delivery, which minimizes carbon residue and extends hardware longevity.

“These are not theoretical claims,” she added. “In extensive field testing, Lilcube consistently outperformed conventional cartridges in terms of vapor quality, flavor retention, and overall user satisfaction when used with live rosin.”

O2VAPE

Like others leading the development of next-generation vaporizers, O2VAPE founder and CEO Dana E. Shoched believes vapes must evolve to meet the market. Since 2013, the company consistently has pushed technology toward more portable, easier to use, and safer designs that address a growing consumer demand for thicker, more complex extracts.

O2VAPE’s most recent introductions rely on all-glass components to meet those objectives. “We engineered both the new Traveler Extreme All Glass Bucket AIO and new postless Glass Nano Pod Kits to vastly improve the vaping experience,” Shoched said. “Currently, many vape devices have components or settings that interfere with the oil. Metal, plastic, and high heat can all impact flavor, stability, and composition, especially with live resin or rosin. So, we eliminated all of that.”

The company believes the Glass Nano Pod Kit is the world’s first patented all-glass nano pod system, bringing the performance of O2VAPE’s popular glass pens to a pod format that allows users to change flavors and oils on the move without changing batteries. The Traveler Extreme features a fully transparent design with all-glass components — tank, center post, and mouthpiece — in half-milliliter and one-milliliter capacities.

Neither the pods nor the AIO need a cotton barrier between the oil and heating elements, leaving glass and ceramic as the only points of contact for vaping liquid. Shoched said the glass components slow oxidation, which contributes to the degradation of extracts over time. Consumers usually notice oxidation as altered flavor. Because O2VAPE’s glass components minimize oxidation, they also may extend products’ shelf life.

CCELL

An independent operating unit of Shenzhen, China-based Smoore Technology Co. Ltd., CCELL is part of a global giant specializing in electronic cigarette research, development, and production. Since 2016, the company has maintained a significant presence in the cannabis vape market and operates a research facility in the U.S.

The company’s most recent innovation, introduced earlier this year, employs a postless tank and a cottonless “bio-heating” system that produces temperatures up to 30 percent lower than many competing products. Lower heat can help preserve terpenes — the flavor and aroma components that are increasingly important to devoted vapers and connoisseurs seeking an experience beyond the high.

MixJoy, which can contain two strains at once thanks to its twin-tank design, was the first hardware to debut with the 3.0 system. Users may enjoy each strain individually or combine the two using a switch on the bottom of the device.

“Our latest advancements include enhanced vapor cloud production and cutting-edge digital and Bluetooth capabilities,” said Corporate Relations Director Nicholas Kovacevich. “We’re particularly excited about our breakthroughs in flavor performance, driven by two key technologies: our Smart Temperature Control, which operates 100°C cooler than traditional vaporizers to prevent flavor distortion from excessive heat, and our Stable Flavor Delivery, which automatically adjusts power to maintain perfect temperature consistency whether a user takes a five-second puff or a thirty-second draw.”

CCELL 3.0 technology also reduces leaks and clogs, Kovacevich said, adding the 100-percent-cotton-free core prevents burnt flavors associated with traditional cores. The postless tank creates a direct path for vapor to travel to the mouthpiece, meaning consumers can experience denser, more flavorful clouds than they may be accustomed to with traditional tanks.

What does the future hold for CCELL? According to Kovacevich, larger tank volumes and new all-in-one formats, both aimed at providing more robust, tailored experiences, are on the drawing table.

SPOTLIGHT

Tech Behind the Trend

Although portable, discreet all-in-one (AIO) vapes are gaining in popularity with consumers across the spectrum, battery-and-cartridge models remain an industry mainstay. In addition to minimizing sustainability issues often associated with disposable AIOs, cartridges allow consumers to switch between concentrates easily as the mood strikes, and many are affordable compared to the recurring costs of AIO replacement.

To meet consumer demand, extractors, brands, and even some dispensaries find themselves filling an ever-greater number of carts with their best-selling oils. Compounding the issue, new strains, new formulations, and new consumer preferences make keeping up with demand challenging.

Thank goodness for technology. Automation has revolutionized cart-filling, turning what once was a tedious, time-consuming, and messy process into a quick and profitable operation. Two automated systems are particularly noteworthy.

Xylem X4

Billed as “the world’s fastest vape cart filling machine,” Xylem Robotics’ X4 allows operations to increase speed, scale, and quality by completely automating cartridge filling and capping. According to Xylem, one X4 machine can replace as many as twenty workers, performing inline filling and capping at a rate of as many as 1,650 units per hour. Precision ceramic pumps, combined with inert gas overlay to prevent oxidation, result in finished carts with leak-resistant vacuum locks and visually higher fill lines with the same gram of oil.

“When people look at a vape produced by our machines, they often want to know why our cartridges look fuller,” said founder and Technical Director Jeff Wu. “It’s because we cap fast and we do it at the lowest temperature possible, and we can deposit the oil at a specific location inside the cart. By [keeping the oil where it belongs], the vape looks full.”

The X4’s low operating temperature also preserves terpenes and decreases product degradation. Consumers notice a clearer, more vibrant extract color and experience more true-to-the-plant aromas, flavors, and effects.

Operating the robotic machines requires human oversight, but the human tasks are quick and easy to perform. Simply load the caps and carts into the X4’s hopper (no trays required), use the large touchscreen to enter custom or preset parameters for cart specifications and concentrate temperature, and push a button. The machine does the rest. Xylem provides training and support on-site or via video chat.

By reducing the cost per unit to manufacture cartridges and allowing staff reallocation instead of hiring more team members, the X4 can exert a powerful influence on an operation’s bottom line. In fact, according to Wu, “most operators generate a return on investment in as little as two months.”

Learn more about Xylem’s X4

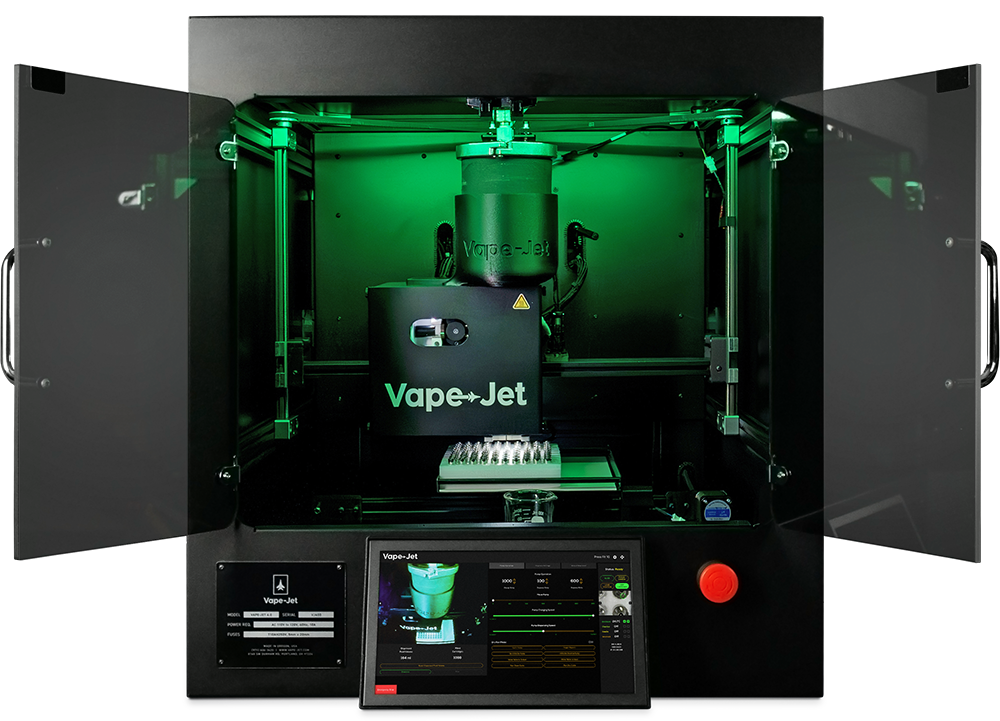

Vape-Jet 4.0 Top Load

The latest evolution of Vape-Jet’s fully automatic platform eliminates inefficiencies and reduces labor costs while preserving terpenes and overall oil quality. Hand-built in Oregon using American-made parts, the Vape-Jet 4.0 Top Load, designed for larger batches and high-volume SKU production, can fill between 5,000 and 10,000 cartridges or AIO devices per shift.

The innovative top-loading feature streamlines processes and reduces downtime. Instead of removing and replacing a physical tank, operators pour oil directly into the top of the machine. Machines can be configured with a two-reservoir stack, doubling oil capacity to two liters.

“Loading extract from the top allows for more rapid changeover of batches,” said Chief Executive Officer Tim Marsh. “We stepped back and thought about how our machine not only does its job but also fits into the broader operational workflow. We realized batch changes were more of a constraint than tray runtime, slowing how many vapes could realistically be filled per day.”

“Now, rather than loading and swapping reservoirs, the machine can essentially be filled directly with pre-heated extract,” he continued. “We eliminated complicated steps and unnecessary [standard operating procedures] to help our customers streamline their operations. This maximizes the uptime of the machine to drive lab throughput.”

“There are also further benefits like a shorter fluid path for even more minimal product loss, less maintenance, and less to clean,” he said. “And most importantly, operators and managers have been loving the new experience.”

Three individual heat zones and a nitrogen-pressurized fluid path help protect product integrity by reducing degradation, evaporation, and oxidation. A pharmaceutical pump and software-based guided calibration procedures help operators consistently hit the desired fill volume.

Training, rapid-response support, and process consultation that includes data analysis and proactive guidance are part of the package.

Learn more about Vape-Jet’s 4.0 Top Load